-

Equipments

EquipmentsOver 100 advanced CNC and precision machining units

-

Certified

CertifiedISO 9001-certified quality management system

-

Capacity

CapacityAnnual output value surpassing 50 million RMB

-

Quality Control

Quality ControlRigorous quality control from design to production

Featured Products

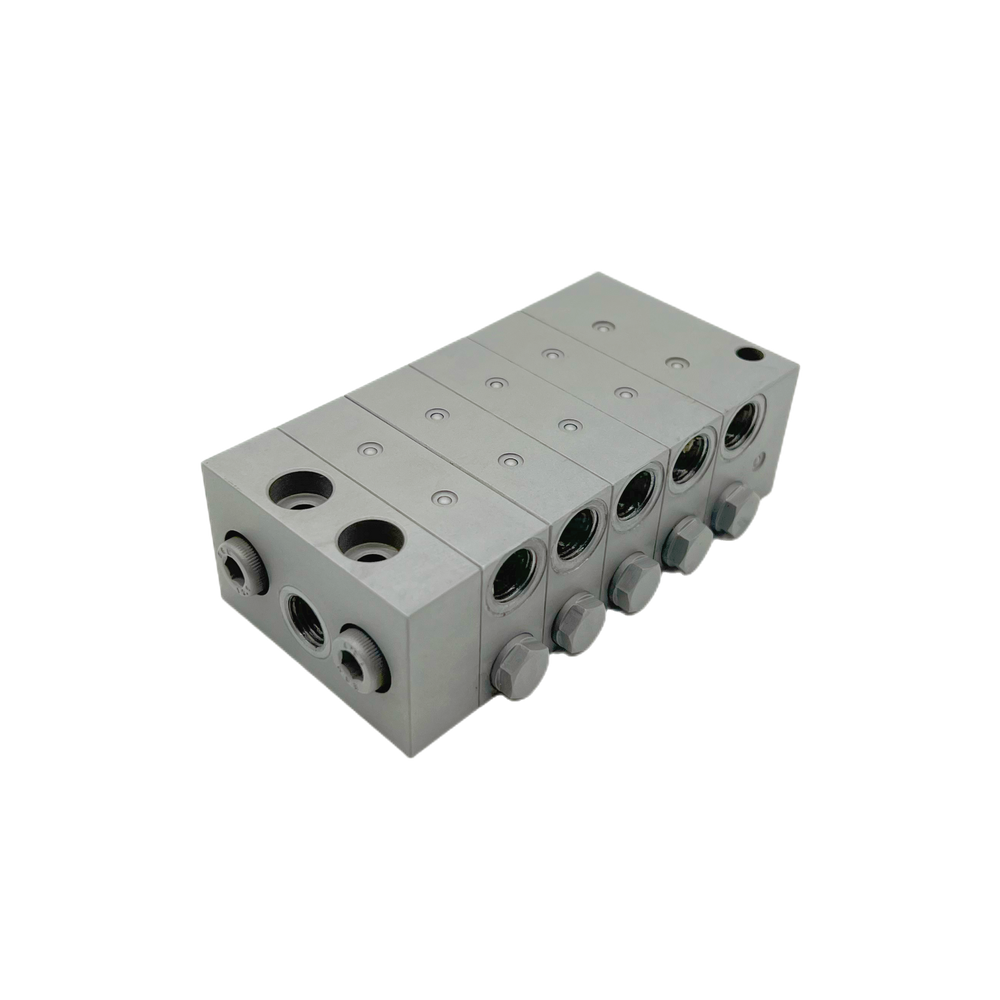

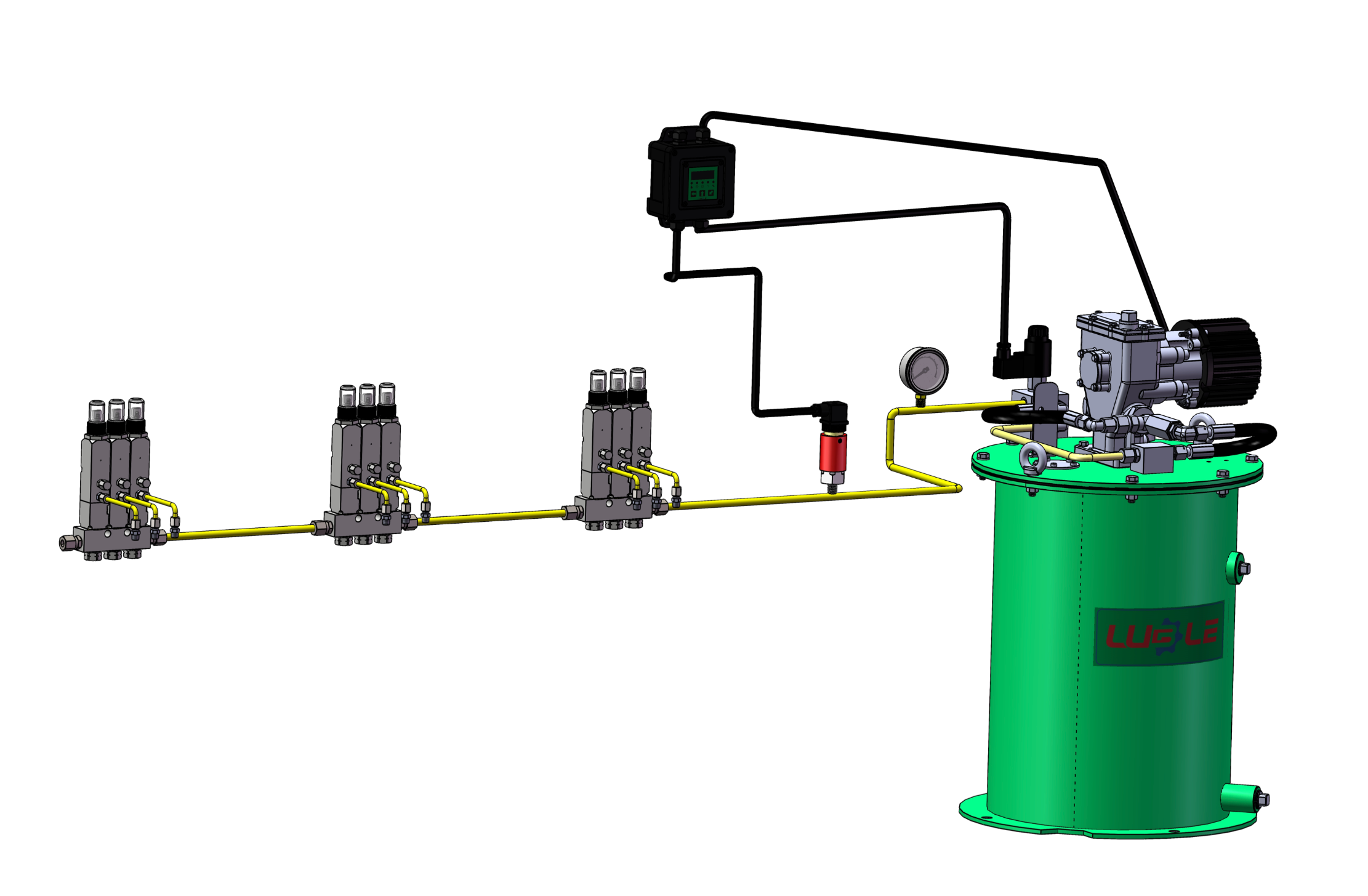

Progressive Lubrication Systems

1. Precise measurement to eliminate waste and insufficient lubrication.

2. Rapid fault location, maintenance efficiency doubled.

3. Compact structure and simplified system layout.

4. Reliable principle and strong durability.

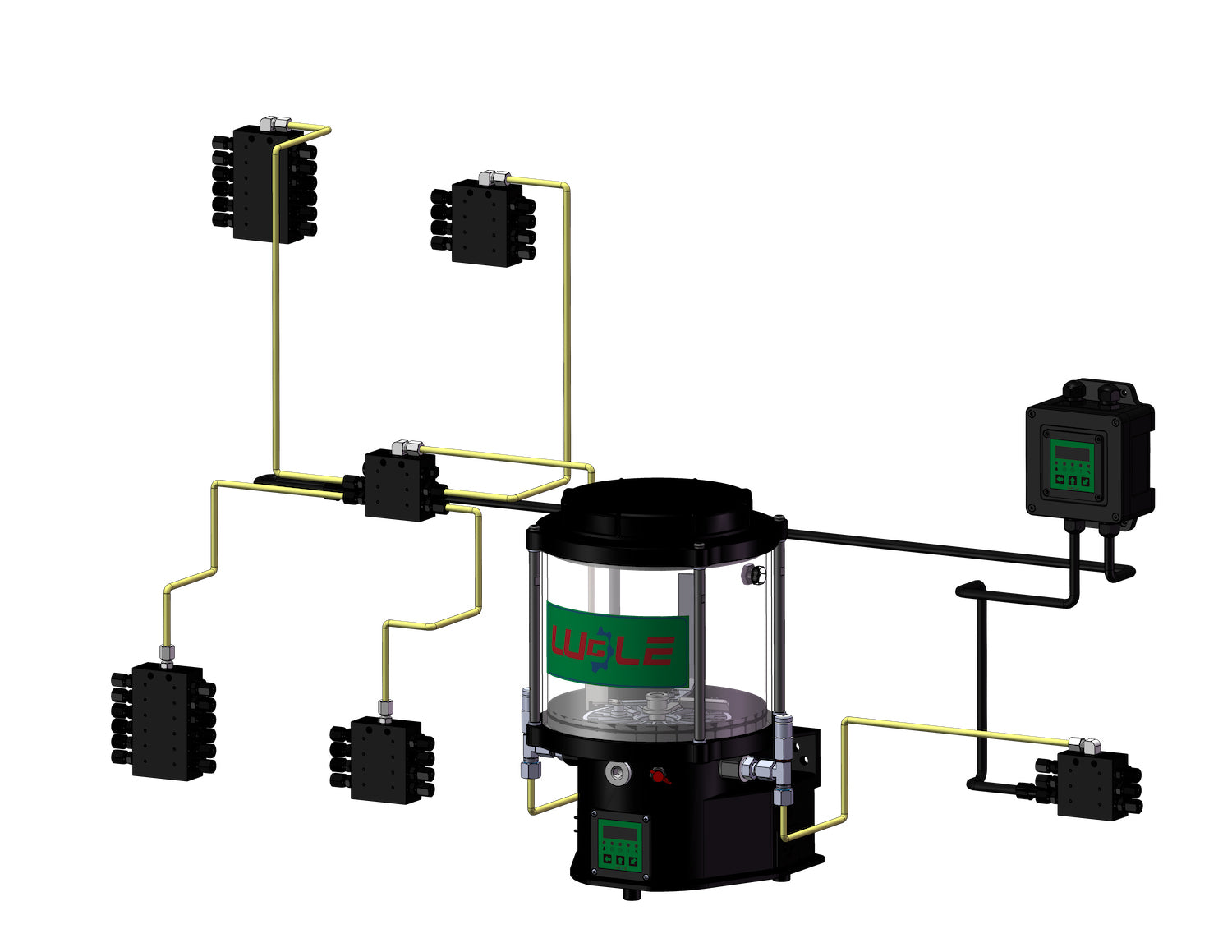

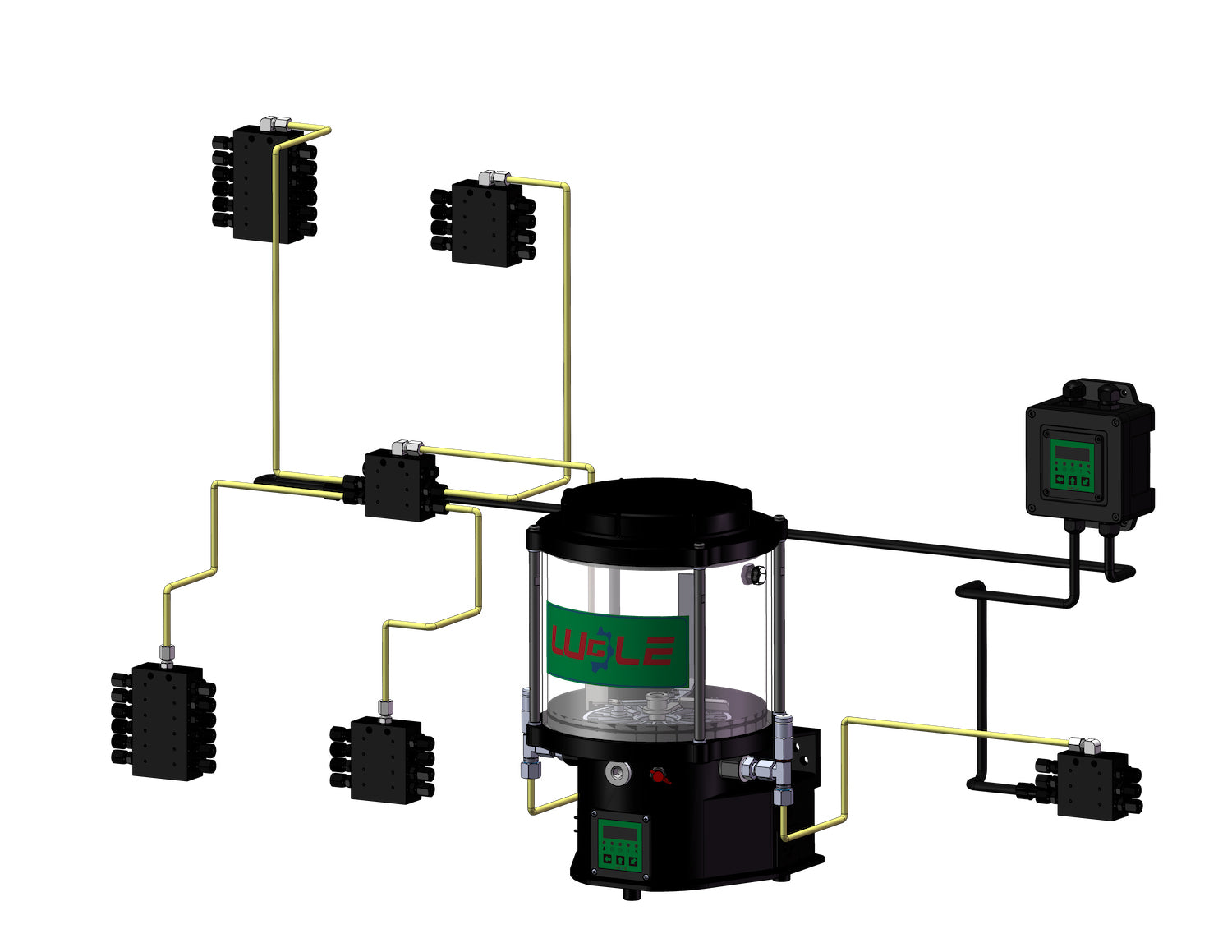

Single-line Lubrication Systems

1. Long distance transportation, wide coverage.

2. Point-to-point independent control without interference.

3. Flexible expansion and easy transformation.

4. Accurate and quantitative oil supply, more detailed monitoring.

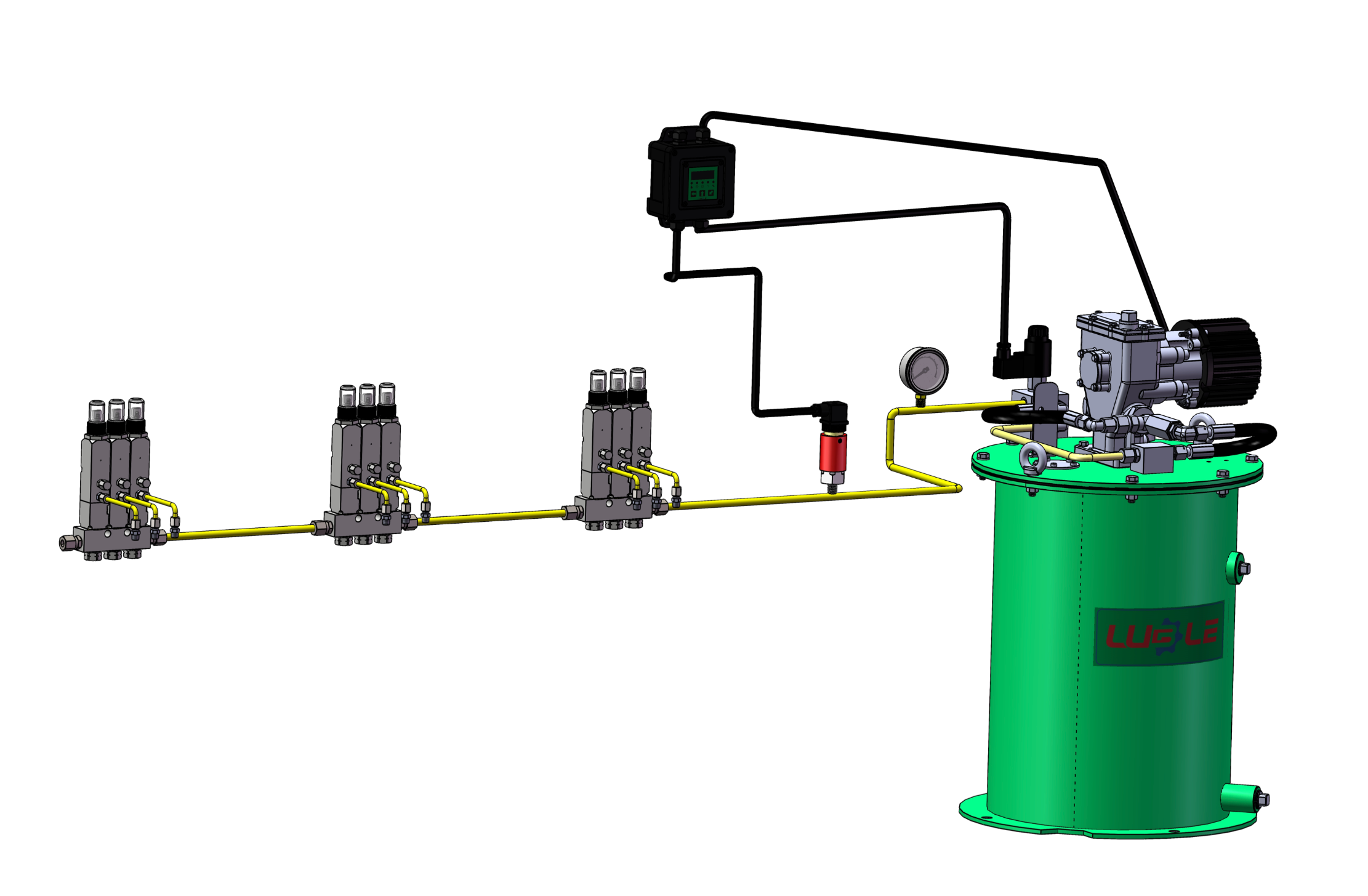

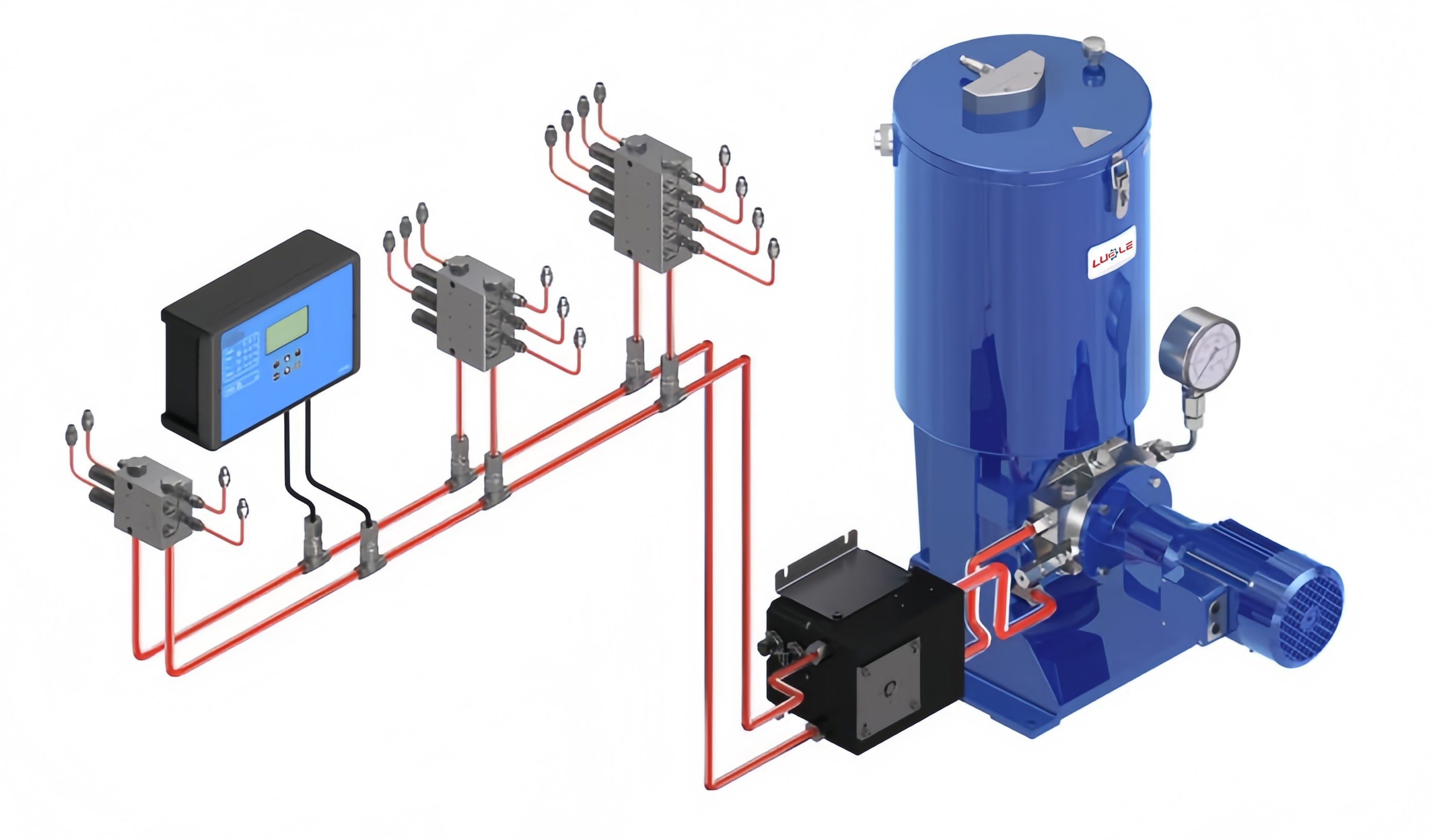

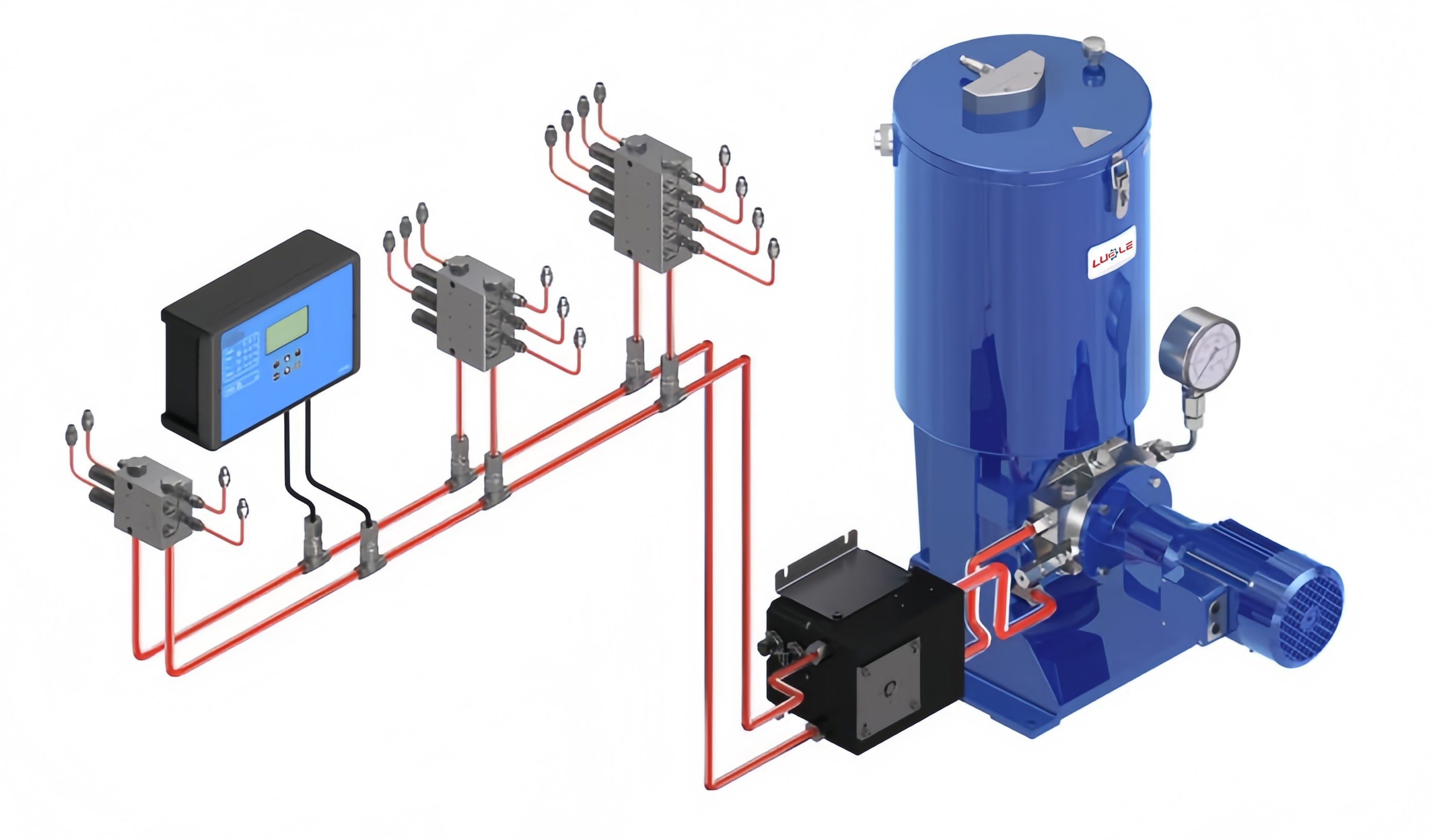

Dual-line Lubrication Systems

1. Super ability to cover a large number of lubrication points.

2. Excellent reliability and anti-pollution ability.

3. The impact of single point failure is small and the system toughness is high.

4. Long distance and large flow transportation.

5. Maintenance is intuitive and simple.

WHy Choose Luble

Founded in 2013, Shanghai Bernoulli Lubrication Equipment Co., Ltd. is a leading high-tech enterprise dedicated to the R&D and manufacturing of industrial lubrication systems. Headquartered in Shanghai, China’s innovation hub, and backed by a state-of-the-art 5,000 m² manufacturing base in Ningbo, we are committed to breaking the monopoly of imported brands and offering cost-effective, high-reliability lubrication solutions for global industrial clients.

Centralized Lubrication System Solutions From Luble

Mining Machinery

Construction Machinery

Wind Power Equipment

Agricultural Machinery

Petroleum Equipment

Steel Metallurgy Equipment

Harbor Facilities

Automation Equipment

Machine Tool Equipment

See What Our Clients Saying About Us

We’ve been using this lubrication system for over a year in our CNC machining line, and the performance has been outstanding. Downtime due to lubrication issues has dropped by over 40%, and overall equipment efficiency has significantly improved. It's a reliable and cost-effective solution we now consider essential.

Our fleet maintenance used to be a major challenge, but after integrating this automatic lubrication system into our trucks, we've seen a noticeable reduction in wear and tear. The system is easy to install, minimizes manual intervention, and extends the life of critical components. Highly recommended for any operation that values long-term equipment health.

Company News

Subscribe to our emails

Subscribe to our emails

Be the first to know about new collections and exclusive offers.