Progressive Lubrication Systems

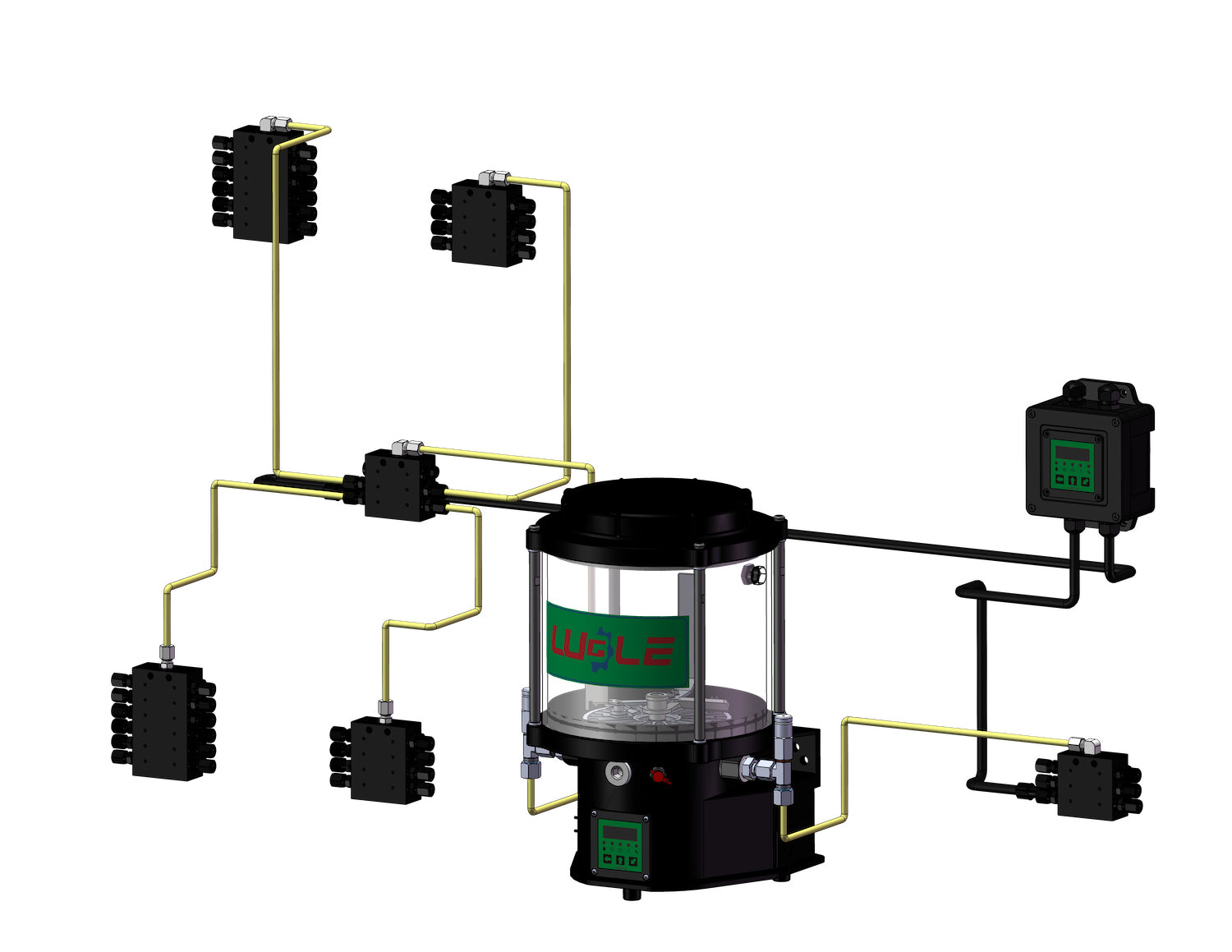

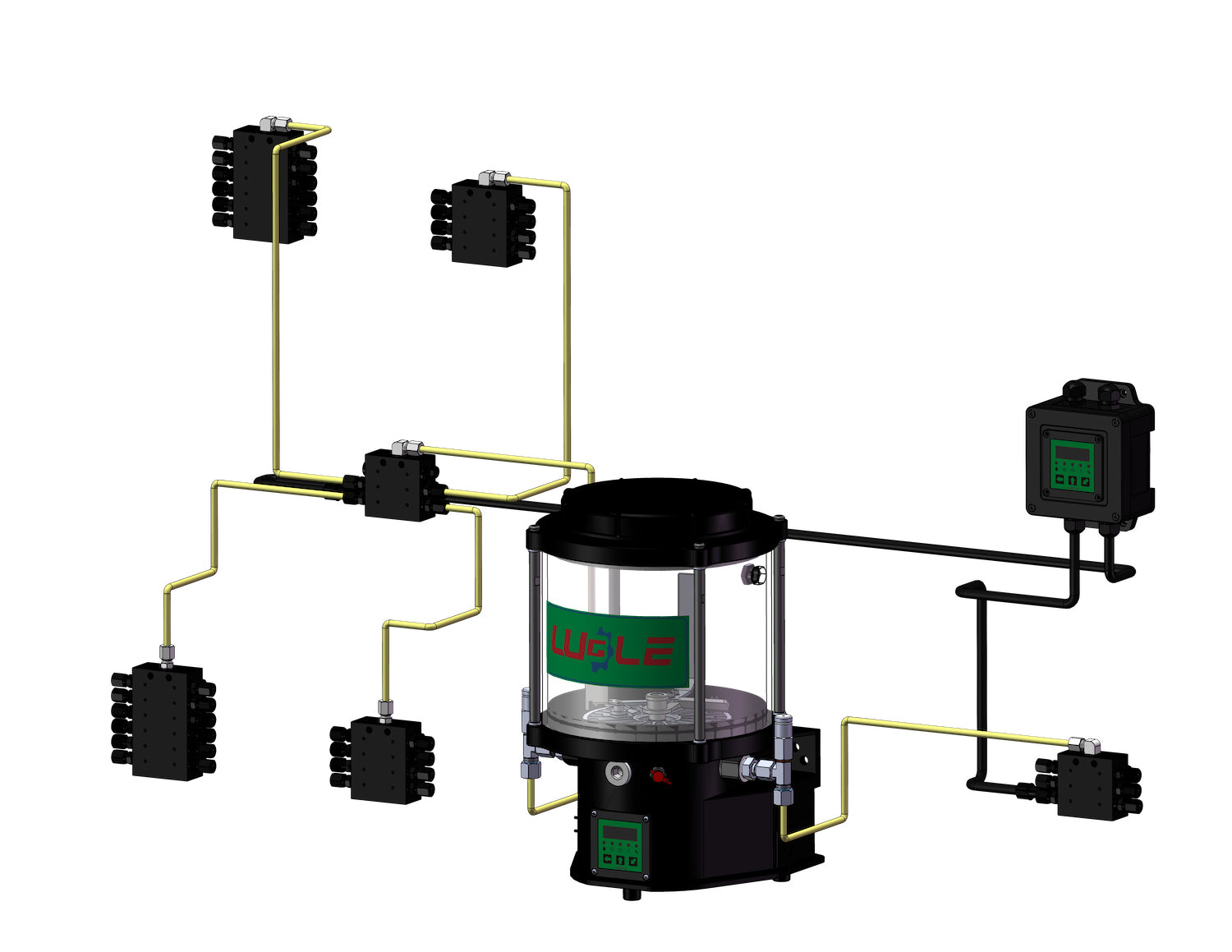

LUBLE's progressive lubrication system distributes the lubricant sequentially to the lubrication points.

1. Precise measurement to eliminate waste and insufficient lubrication:

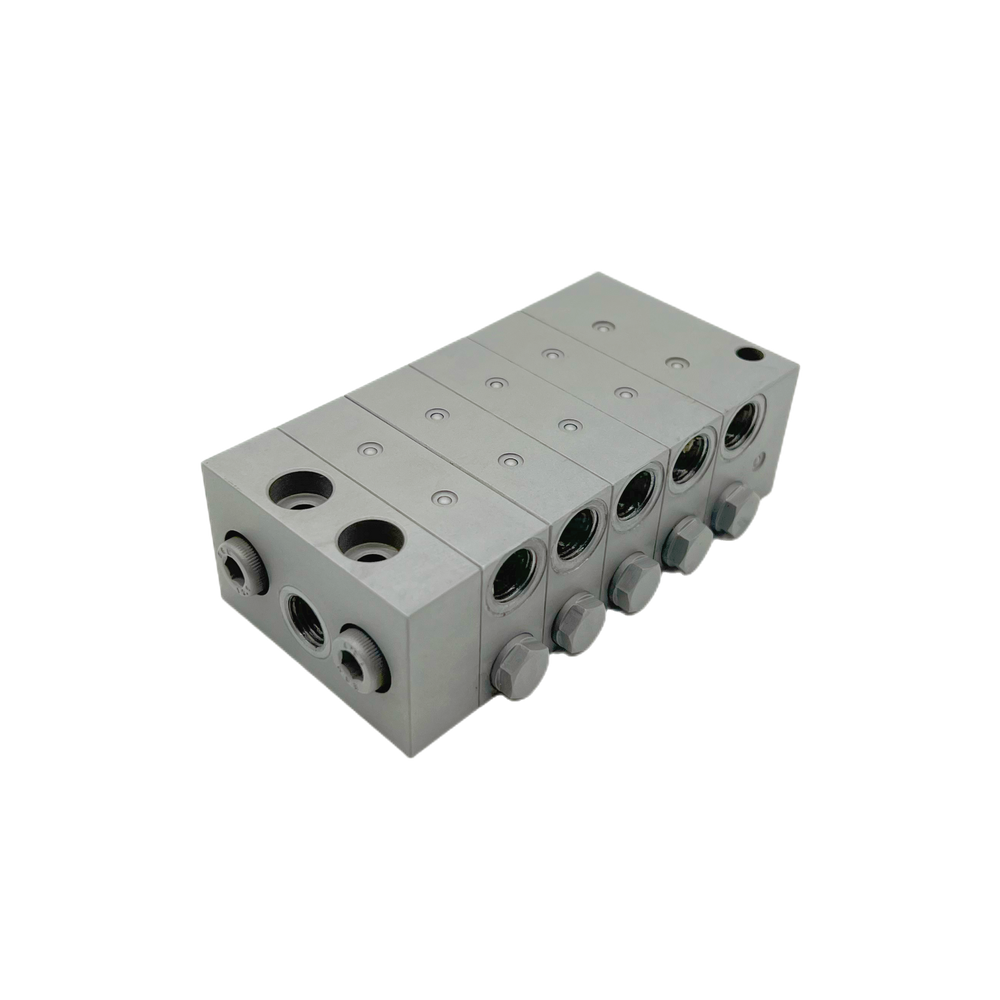

The core of the system, the progressive distributor, has a built-in precision metering piston. Each piston must complete a full stroke to trigger the next piston. This forced sequencing mechanism ensures that each lubrication point receives a pre-set and precise dose of grease in each cycle, avoiding waste and eliminating the risk of equipment wear due to insufficient oil supply.

2. Rapid fault location, maintenance efficiency doubled:

"One block and all stop" is its core monitoring logic. If any lubrication point is blocked, the corresponding piston cannot complete the stroke, and all subsequent pistons cannot act. At this time, the main circuit pressure may be abnormally increased significantly, or the signal from the specific travel sensor may be lost. The monitoring device can give an alarm immediately.

3. Compact structure and simplified system layout:

The progressive distributor of LUBLE can usually be divided into 6 to 24 or more outlets to meet the needs of multi-point lubrication. Compared with independent pumps or complex branch pipelines for each point, the system structure is extremely compact and significantly saves installation space, especially suitable for modern mechanical equipment with limited space (such as engineering machinery, wind power gearbox).

4. Reliable principle and strong durability:

The system works based on pure mechanical sequential drive (pressure pushes the piston), with simple and direct principle and strong adaptability to harsh industrial environment (such as vibration and temperature difference). Compared with the system relying on complex electronic control, its operation is more stable and reliable, and its maintenance requirements are low.

- En vedette

- Meilleures ventes

- Alphabétique, de A à Z

- Alphabétique, de Z à A

- Prix: faible à élevé

- Prix: élevé à faible

- Date, de la plus ancienne à la plus récente

- Date, de la plus récente à la plus ancienne

-

Equipments

EquipmentsOver 100 advanced CNC and precision machining units

-

Certified

CertifiedISO 9001-certified quality management system

-

Capacity

CapacityAnnual output value surpassing 50 million RMB

-

Quality Control

Quality ControlRigorous quality control from design to production

Subscribe to our emails

Subscribe to our emails

Be the first to know about new collections and exclusive offers.